The selection of the range of the ammonia gas module wholesale can be determined through a comprehensive evaluation based on factors such as the maximum weighing capacity of the scale, the number of ammonia gas module wholesale selected, the self-weight of the scale body, the possible maximum eccentric load and dynamic load, etc. Generally speaking, the closer the range of the ammonia gas module wholesale is to the load allocated to each ammonia gas module wholesale, the higher the accuracy of its weighing will be. However, during practical application, since the loads applied to the ammonia gas module wholesale include not only the object being weighed but also the self-weight of the scale body, tare weight, eccentric load, vibration and shock loads, etc., when selecting the measurement range of the ammonia gas module wholesale, many aspects of factors need to be considered. Ensure the security and lifespan of the ammonia gas module wholesale.

The following presents an empirical formula that has been verified through many experiments.

The formula is as follows:

C=K0 × K1 × K2 × K3 (Wmax+W)/N

In the formula, C represents the rated range of a single ammonia gas module wholesale

W - Self-weight of the scale body

Wmax - The maximum gross weight of the object being weighed

N - The number of support points selected for the scale body

K0 is a safety factor, generally ranging from 1.2 to 1.3

K1 - Impact coefficient

K2 - the center of gravity offset coefficient of the scale body

K3 - Wind pressure coefficient

Based on experience, the weighing ammonia gas module wholesale should generally operate within 30% to 70% of its measurement range. However, for some weighing instruments that have a relatively large impact force during operation, such as dynamic rail scales, dynamic truck scales, steel scales, etc., when choosing weighing ammonia gas module wholesale, it is generally necessary to expand its measurement range. Enable the weighing ammonia gas module wholesale to operate within 20% to 30% of its range, thereby increasing the weighing storage range of the weighing ammonia gas module wholesale. To ensure the application security and lifespan of the weighing ammonia gas module wholesale. The selection of the ammonia gas module wholesale type for weighing primarily depends on the type of weighing and the equipment space to ensure that the equipment is suitable and the weighing is safe and reliable. On the other hand, the suggestions of the ammonia gas module wholesale manufacturing plant should be considered for weighing. The manufacturer generally stipulates the application plan of the weighing ammonia gas module wholesale based on the force conditions, functional policies, equipment methods, structural types, and materials of the elastomers and other characteristics of the weighing ammonia gas module wholesale. For example, the aluminum cantilever beam weighing ammonia gas module wholesale is applicable to pricing scales, platform scales, platform scales, etc., and the steel cantilever beam weighing ammonia gas module wholesale is applicable to hopper scales, electronic belt scales, sorting scales, etc. The steel bridge-type weighing ammonia gas module wholesale is suitable for rail scales, truck scales, crane scales, etc. The column-type weighing ammonia gas module wholesale is suitable for truck scales, dynamic rail scales, large-tonnage hopper scales, etc.

2. Selection of accuracy level for weighing ammonia gas module wholesale

The accuracy grades of the weighing ammonia gas module wholesale include technical policies such as nonlinearity, creep, repeatability, hysteresis and sensitivity of the weighing ammonia gas module wholesale. When choosing, one should not blindly seek high-grade weighing ammonia gas module wholesale. The accuracy grade and cost of the electronic scale should be considered. Under normal circumstances, the root mean square value of the sum of the three policies of nonlinearity, non-repeatability and lag for the total accuracy of the weighing ammonia gas module wholesale is slightly higher than the accuracy of the scale.

3. Application plans for various types of weighing ammonia gas module wholesale

The selected weighing ammonia gas module wholesale must meet the requirements of surface input sensitivity, must be compatible with the selected surface, and meet the accuracy requirements of the entire electronic scale. An electronic scale is primarily composed of three parts: the mechanical structure, the weighing ammonia gas module wholesale, and the surface. When choosing the accuracy of the weighing ammonia gas module wholesale, The accuracy of the weighing ammonia gas module wholesale should be slightly higher than the theoretical calculation value, because the theory is generally constrained by objective conditions. Factors such as the strength of the mechanical structure, the function of the surface, and the harshness of the working environment of the scale all directly affect the accuracy of the scale. Therefore, demands should be made from all aspects, economic benefits should be coordinated, and the goal should be achieved.

4. Application environment

Under normal circumstances, high-temperature environments cause problems such as the melting of coating materials, the opening of solder joints, and structural changes in the internal stress of the elastomer for weighing ammonia gas module wholesale. The influence of dust and moisture on the short circuit of the ammonia gas module wholesale for weighing; In an environment with high corrosiveness, it may cause damage to the ammonia gas module wholesale elastomer or result in a short circuit. The electromagnetic field will interfere with the output of the weighing ammonia gas module wholesale. Under the corresponding environmental factors, it is necessary for us to select the corresponding weighing ammonia gas module wholesale in order to meet the necessary weighing requirements.

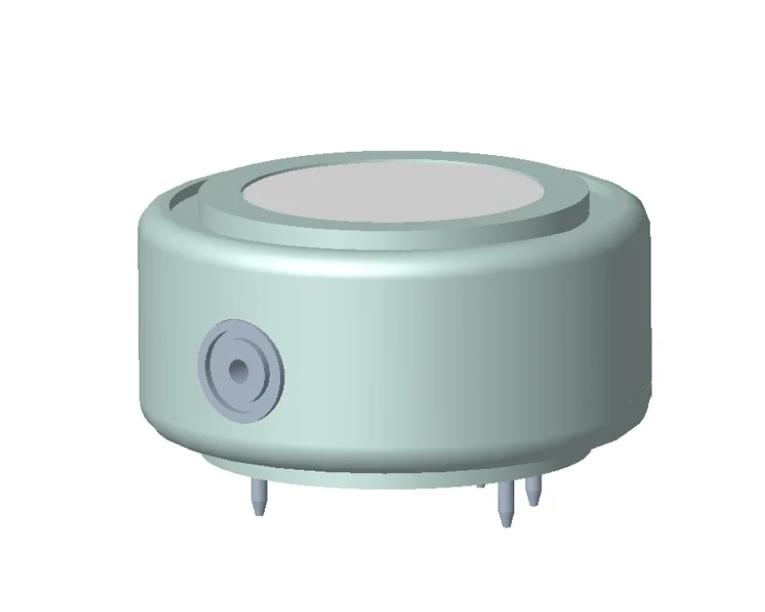

ammonia gas module wholesale https://www.cnprosense.com/Gas-detection-module